The Quality of Roof bolting is a key factor for safe and productive mining in underground operations. Early load bearing capacity and corrosion protection by full column grouted bolts are simply achieved by use of bolting resins. Those can be installed as cartridges or pumped into the bore hole in order to seal the bolts over all the length.

Anchoring of rockbolts and cable bolts with POTENTIA® Thixo and POTENTIA® Thixo High Performance

This system provides a full column resin grouted installation which, helps assure a more effective bolt installation as well as providing corrosion protection of the bolt.

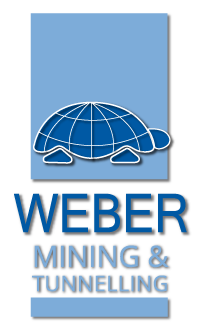

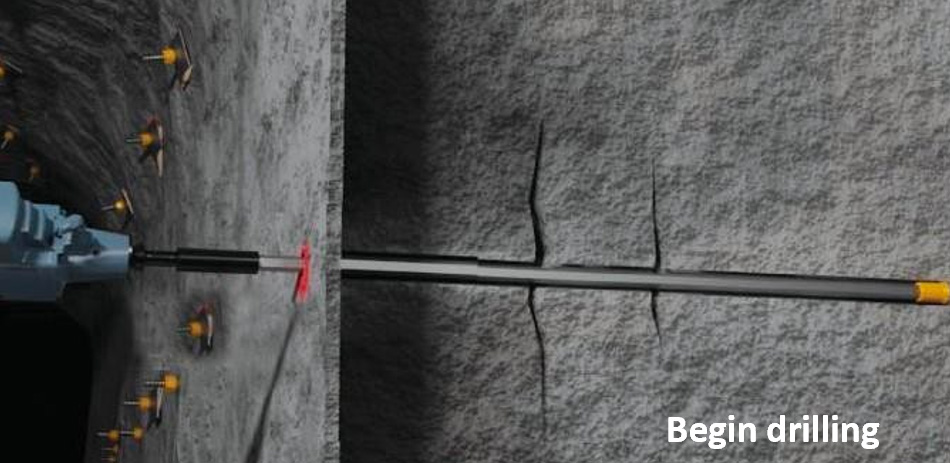

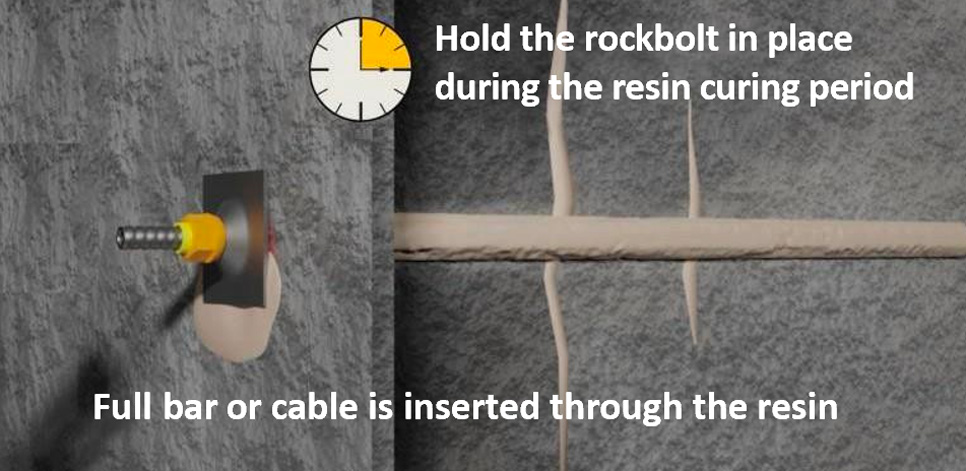

Bolts are ready for tensioning in a short time, thus providing for quicker support. It can be applied to the conventional 2-stepsystem whereby the bolt is placed after the borehole was drilled with a drill steel or it can also be combined with a self-drilling anchor. This application using self-drilling anchors is particularly useful in ground conditions where drilled holes are prone to collapse due to bad ground conditions.

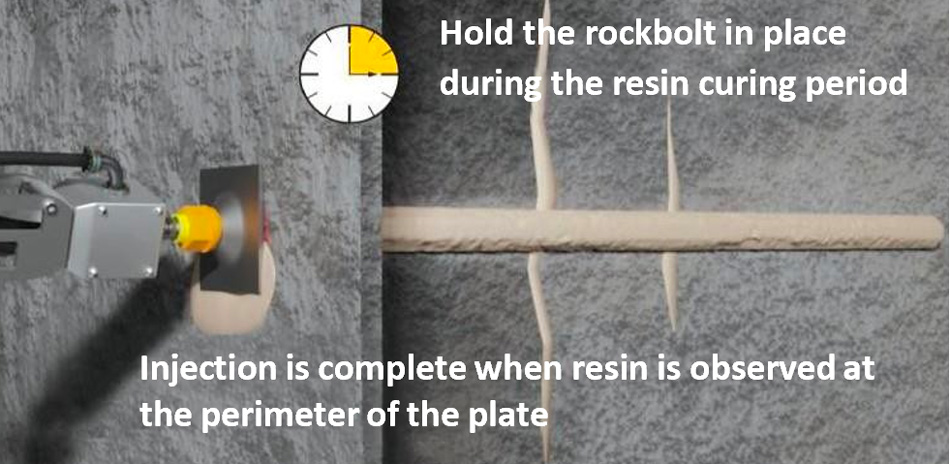

After the annulus between bolt and borehole is injected, an immediate load transfer can be ensured as the resin cured after a few minutes.

Advantages

- Full column grouting.

- Suitable for wet ground condition.

- Suitable for weakened and weathered rock formations.

- Increased load bearing capacity.

- Highly fractured areas can be consolidated during this installation process.

- Applicable to SDA, conventional cable anchors and any other bolting system which allows for injection of grouts.

This is the title

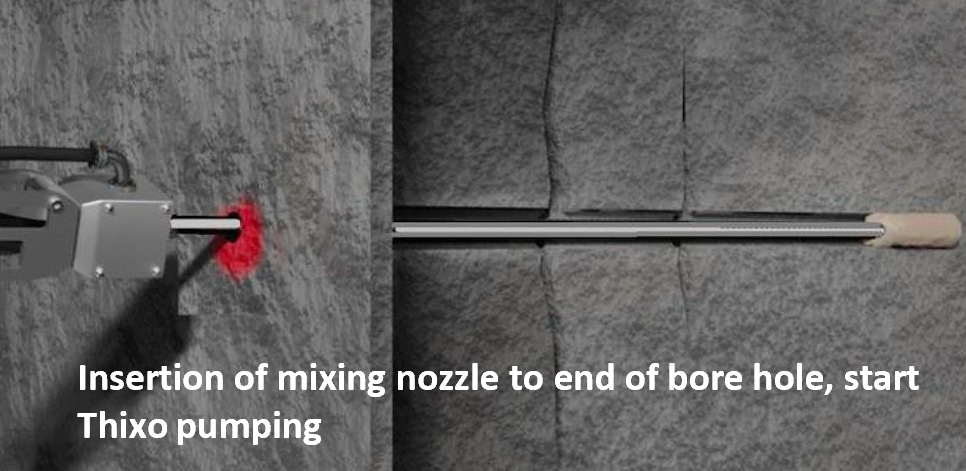

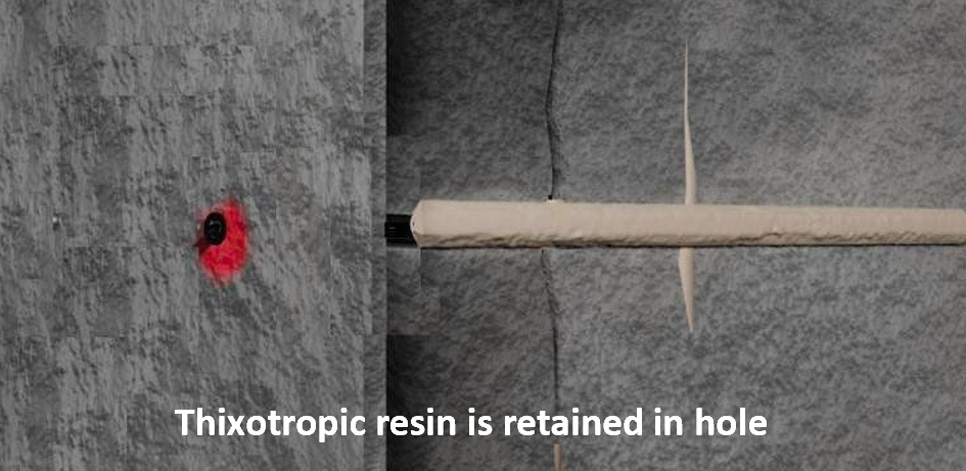

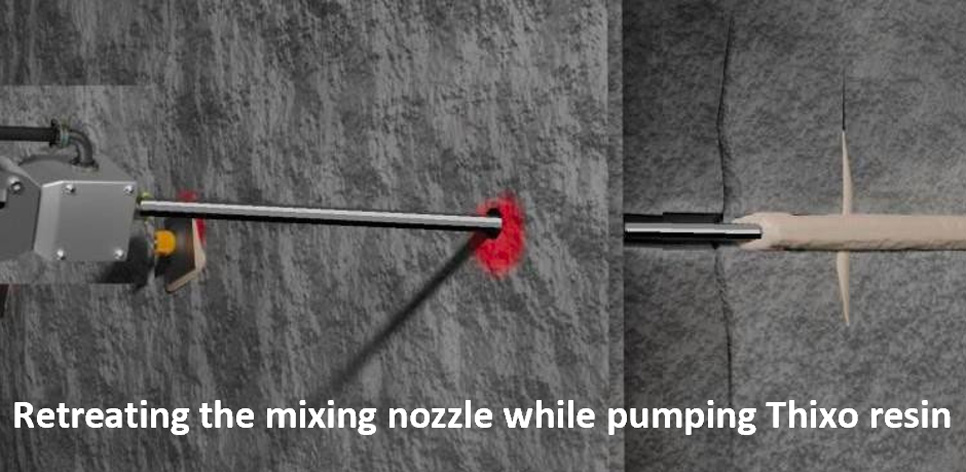

PRE-GROUTING

Potentia® Thixo / Marisil® Thixo pre-grouting is used when installing solid bar rockbolts or cable bolts.

This is the title

This is the title

This is the title

This is the title

Pumpable resins for bolting (Potentia® Thixo, Marisil® Thixo) are the latest technology for grouting bolts and cables, enabling a fully automated bolt installation. Unlike resin cartridges, pumpable resin ensures full column encapsulation regardless of the hole size. Boreholes can be pre-grouted, followed by the insertion of a solid bar, rockbolt or cable, or post-grouted using a pumpable rockbolt (SDA). Setting times and thixotropy are tailored to the site conditions, taking the length of the bolts/cables and the temperature on site into account.

Benefits of the pumpable resins:

- Full column grouting.

- Significantly reduce the installation time (Quick installation cycle)

- Enables automated bolting

- Resin penetrates even the most minor cracks

- Adjustable setting time

- Pumpable resins have multiple applications - Usable With Hollow and Cable Bolts

- Non foaming

- Gels immediately after mixing

- Quick curing to full strength

- Does not intermix with water

Technical datasheet and further information