Adequate ventilation is a prerequisite for any underground mining operation. It is necessary to reduce the losses of fresh air, cross contamination with return air, to prevent gas build up(e.g. Methane) by filling non ventilated cavities and to seal off old works to prevent underground fires. We offer solutions to seal areas, creating air tight ventilation seals which will aid underground ventilation requirements.

Foam Ventilation barrier at the T-junction area and goaf sealing :

At the intersection between the coal face and the gate road, the airflow from the bottom roadway has a tendency to head straight for the caved goaf. This causes a risk of methane release and build up at the top end of the face. Therefore it is important to control the airflow entering the goaf area and to direct it instead through the longwall face by constructing an air barrier at the bottom end of the face line. This system also reduces the risk of spontaneous combustion within the goaf area.

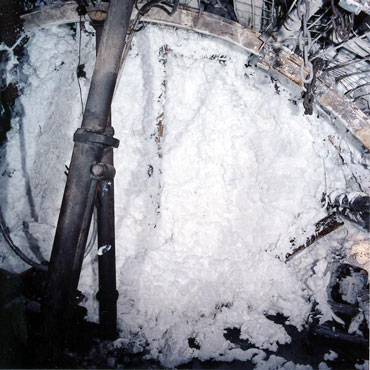

A lightweight shuttering is raised using mesh panels and textile sacking (if necessary). The shuttering is placed between the last face support and the roadway wall opposite the bottom road. The product is applied using a metering pump and mixing gun.

Depending on the type of product and the ambient temperature, the operation can be performed by pumping foam between the two 'skins' of shuttering or by direct application to mesh panels. Such barriers can be constructed quickly and easily due to the rapid curing times and high expansion rates of the recommended products.

Technical datasheet and further information

An additional airtight barrier can be created by injecting the product into the goaf cavities behind the shield support. This method not only prevents fresh air escaping into the goaf area, but also reduces the gas inflow along the length of the Long Wall.