When the coal face crosses a Fault Zone or the heading takes place in an area with geological discontinuities, the safety for this operation is endangered without proper safety precautions. We provide solutions to reinforce the affected zones and to prevent rock falls.

Technical datasheet and further information

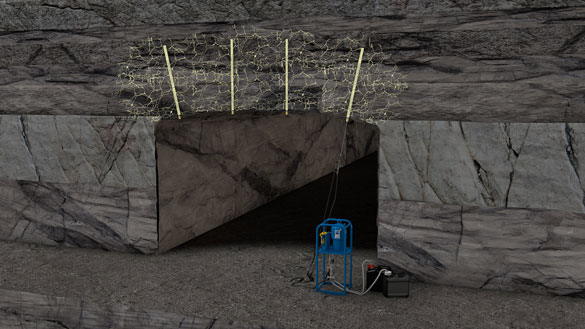

Depending on the local strata conditions, injection boreholes are drilled according to a pre-established pattern. The distribution of geological discontinuities determines whether the boreholes are located just in the coal face or also in the roof and the side walls or ribs. The boreholes are fitted with injection pipes and packers. In fragmented rock zones a self-drilling-anchor (SDA) is used to guarantee a stable injection hole, where problems are encountered with holes closing during the drilling process.

A metering pump injects the product through the pipe or SDA into the ground. Due to the low viscosity the resin penetrates the smallest cracks and fissures. After polymerisation the product develops a high adhesive strength and flexibility which ensures effective strata cohesion. The type of resin depends on the in-situ ground conditions like temperature, presence of water, fire risk, local regulations, etc.